Convenience Through Automated Settings

The Flexinspect BC Generation III is a reliable and uniquely configurable platform that easily allows inspection functionality to be added as required. All adjustments are fully motorized providing unmatched repeatability and shortest job change times giving glassmaker flexibility and value.

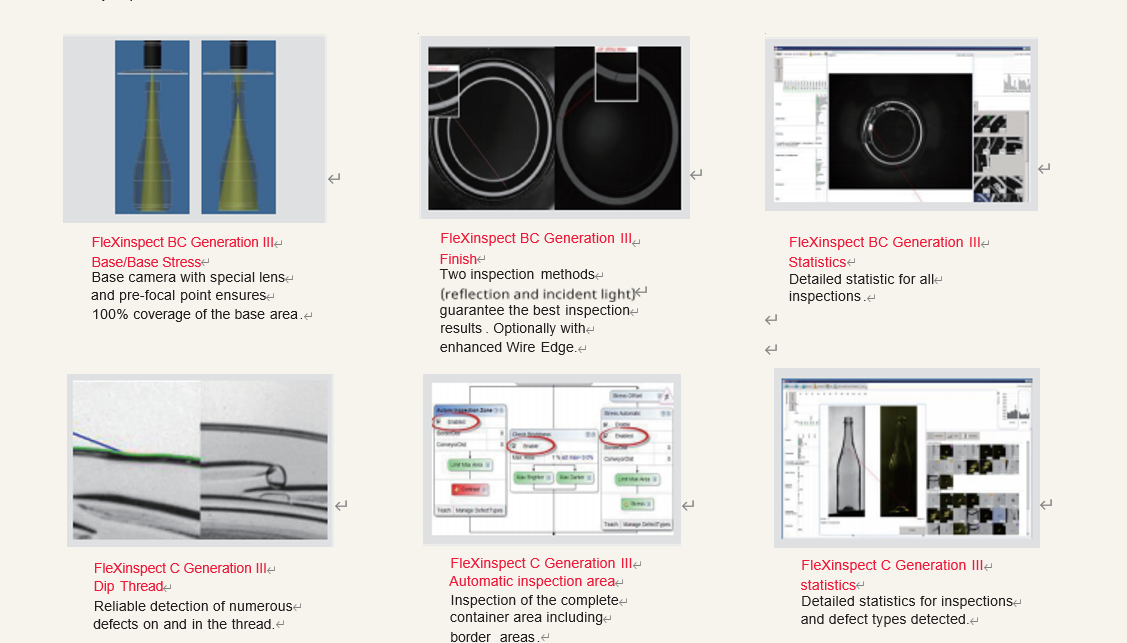

The B side with its high-resolution cameras and special optics inspects the complete bottom area with advanced algorithms including stipple and baffle filters (also for non-round).

The C side is a Sidewall inspection machine with 6 IntelliLED(programmable LED) light sources and high-resolution cameras. Dedicated light sources for each of the symmetrical views allow the highest level of inspection available including dimensional. When equipped with a mold reading option, the Flexinspect BC Generation III mold-correlates results.

Unmatched Inspection Accuracy

High resolution camera technology for maximum

defect detection

Programmable long life LED illumination providing

repeated, accurate results

Job Portability And Repeatability

Jobs can be programmed on one machine and

automatically set on the rest of your machines

Symmetrical Optical Setup

Once a job is selected all inspection machines

automatically adjust to suit that container

Improved repeatability and invariance to

container orientation

Touch Free Optics

Sealed cameras reduce the chance of damage

and the need for cleaning

Features

– Quick job change for new articles , fully automatic recall of previous jobs , no manual adjustments

– Dust proof optical assemblies (cameras&lights) and air conditioned electrical enclosures

– Cavity correlation of all defects

– Traceability of change (who ,what ,when)

– Independent belt position for tapered ware

– 4 - Servo driven carry belts

– Integrated 21.5” touch display

– High resolution camera standard

Available Inspections

B-Side

– Base Inspection

– Base Stress

– Sealing Surface Finish 1

(reflective light)

– Sealing Surface Finish 1

(reflective light)withwireEdge

– Sealing Surface Finish 2

(incident light)

– Vision mold number reader in base station (heel code sand base codes-top down)

– Smart vision mold number reader (seven segment base codes-top down)

C-Side

Sidewall 6 views

– Dimensional 6 views

– Sidewall low contrast / transparent

– (cosmetic) 6views

Sidewall stress 6 views

– Sidewall shoulder 6 views

– Tall ware Sidewall shoulder 6 views

– Tall ware Sidewall shoulder stress

– 6 views

Dip / thread for wide mouth

– (anoption for all jar lines)

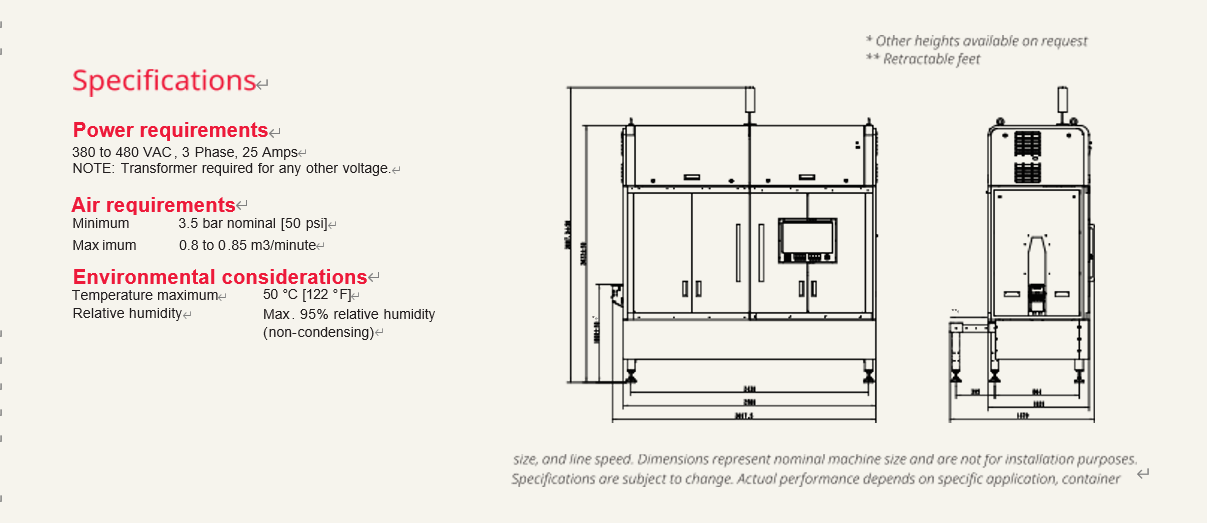

Ware Range

– Height : 40mm-350mm up to 440mm optional

– Body Diameter: 15mm-160mm

– Finish Diameter: 4 .5mm-120mm

Typical Production Speeds

Type Production Speed Burst Speed

Beer | 300-500 | 600 |

Wine | 250-400 | 450 |

Baby Food | 300-500 | 600 |

Non Round | 100-300 | N/A |

Address: No. 577 Xinhua Avenue, Zhoucun District, Zibo, Shandong: 86-533-6181717

Copyright © Shandong Sanjin Glass Machinery Co., Ltd. all rights reserved, Lu ICP, No. 09074865.